High Speed Slicers

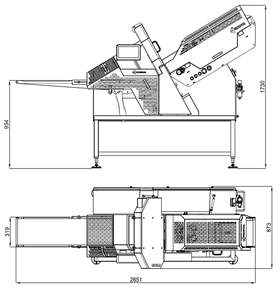

Slicefil-300

|

Technical data:

Options (not included): Conveyor with customized length to deliver portions to a thermoformer. Integrated Touch screen of 10”. Special gripper for soft products (cheese, cooked ham, or similar). |

Automatic Slicer Slicefil-300The new automatic slicer SliceFil-300 stands out for its simplicity of use, compact dimensions, high performance and variety of use, its use indicated in industries of medium production of cured or cooked sausages, ham and cheese. The product is loaded manually and is supported by a clamp. The cut is made through a circular type blade, by cutting the product with great precision and placing it in stacked portions, staggered batches, or other presentations, on the synchronized advance output belt.

Features:

|

Filet-611

|

Options:

- Fold device of slices. Ref. ITE0600010C

- Product support conveyor synchronized with gripper to prevent “spring” effect and difference in thickness of the slices.

- Incorporated lade sharpener.

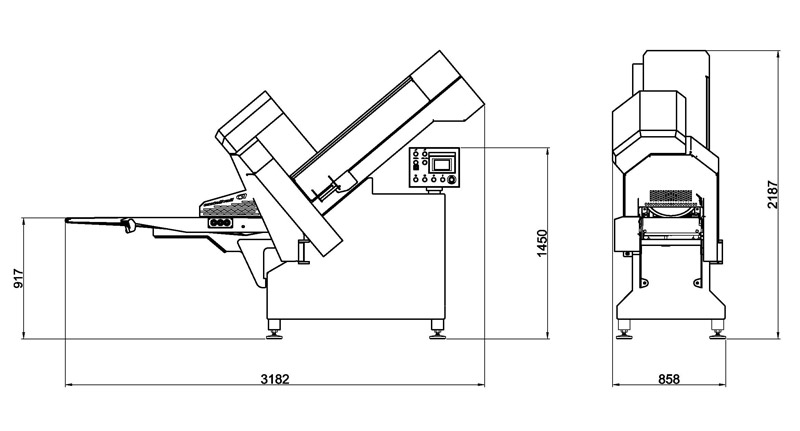

Filet-615

- Heavy duty construction made of Food Grade -304 stainless steel.

- The Fillet - 615 slicer is ideal for shingling and stacking cured, cooked and raw meats as well as cheese and vegetables

- 150 mm output conveyor and 500 mm length separating conveyor with automatic 70 mm vertical tilting.

- The product to be cut is attached to a gripper with automatic handling.

- Vertical and lateral pneumatic pusher-plates with pressure adjustable from the control panel.

- Product presentation: stepped, stacked, stepped-stack, individual slices, “shaved-meat”, oval shapes, one row beside another and many different programmable presentations. The number of slices in each group may be changed according to requirements, as well as the length of the portions and the separation between portions.

- Cutting system - both circular and orbital rotation, with independent motors and independent speed control through the control panel. The cutting settings are managed throughout a touch screen.

- Easy adjustment of all settings using the touch sensitive screen of 10”.

- Continuous portion weight control.

Options:

- Interleaver paper maximum 220 mm. Alternatively, 3 rolls of 90 mm/each in parallel. Ref.ITE0615015C

- Dynamic weighing scale. Weighing table length 450 mm. Width weighing table 400 mm. Speed weighing 80-100 portions / minute. Maximum portion weight 1000 gr. Ref. ITE0600003C.

- 500 mm flip/flop rejecting conveyor. Ref. ITE0600009C.

- 2000 mm long upper conveyor-belt for checking rejected portions. ITE0600006C.

- Side rejection conveyor-belt. Width: 400 mm and length: 600mm. Side rejection in the same lower conveyor-belt. Ref. ITE0615016C

- Output conveyor for thermoforming machine. Width=500 length 3000 mm.Ref. ITE0600005C

- Folding device of slices. Ref.ITE0600010C

Technical details:

Air Pressure 6 bar

Weight From 600 to 1300 k

Slice Thickness From 0,5 to 100 mm

Output 400 slices/min

Power From 6 to 11 kW

Dimensions (depends on its configuration) 5071-5729 x 1146 x 1928 mm

Air Pressure 6 bar

Weight From 600 to 1300 k

Slice Thickness From 0,5 to 100 mm

Output 400 slices/min

Power From 6 to 11 kW

Dimensions (depends on its configuration) 5071-5729 x 1146 x 1928 mm

Filet-620

- The FILET - 620 slicer is ideal for cutting and stacking cured, cooked and raw meats as well as cheese.

- The portioning conveyor is 250 mm long, the separating conveyor is 500 mm in length with automatic vertical tilt up to 70 mm.

- Automatic product gripper with sensor.

- Vertical and lateral pneumatic pusher-plates with pressure adjustable from the control panel.

- Product presentation: stepped, stacked, stepped-stack, individual slices, “shaved-meat”, oval shapes, one row beside another, different programmable figures, etc. The number of slices in each group may be varied according to requirements, as well as the length of the portions and the separation between portions.

- Cutting system, both circular and orbital rotation, with independent motors and independent speed control through the control panel.

- Easy adjustment of all settings using the touch sensitive screen of 10″.

- Pneumatic gripper.

Options:

- Interleaver maximum 220 mm. Alternatively 2 rolls of 100 mm/each in parallel. Ref. ITE0600002C

- Dynamic weighing scale. Weighing table length 450 mm. Width weighing table 400 mm. Speed weighing 80-100 servings / minute. Maximum weight portion 1000gr. Ref. ITE0600003C.

- 500 mm tipping rejection conveyor for rejecting the portion on upper conveyor-belt. Ref. ITE0600009C.

- Side rejection conveyor. Width: 300 mm and length: 500 mm. Side rejection in the same lower conveyor-belt. Ref. ITE0600004C.

- 2000 mm. long upper conveyor for checking rejected pieces. Ref. ITE0600006C.

- 2000 mm. long lower conveyor to move portions to the thermoforming machine. Ref. ITE0600005C.

- Portions design through portioning belt insertion movements that allow presenting the product in round plates, different figures, etc. Ref. ITE0600007C.

- Lateral displacement of 150 mm. Software portions design. Ref. ITE0600007C.

- Fold device of slices. Ref. ITE0600010C.

- Connection to scanner “ECO-SCANNER”. Ref. ITE06500002C.

|

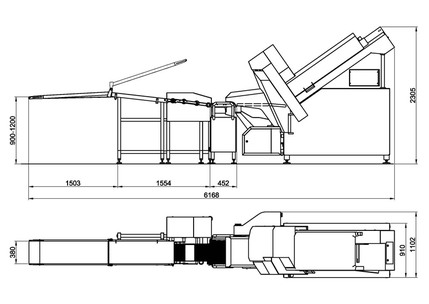

Technical details:

Dimensions (mm) 6635x1105x2305 Maximum length of the product to be cut 1,200 mm Maximum cross section cut product 250x150 mm (width x height) Slicer thicknessAdjustable from 0,50 to 100 mm Blade diamter 450 mm Production Up to 600 cuts/minute Electric power 9 kw to 12 kw Air pressure 6 bar Weight From 1,000 kg to 1,700 kg |

Filet-650

- Heavy duty construction made of Food Grade-304 stainless steel.

- The Filet 650 slicer is ideal for shingling and stacking cured, cooked and raw meats as well as cheese.

- The portioning conveyor is 250 mm long , the separating conveyor is 500 mm long with automatic vertical tilt up to 70 mm.

- Automatic product product with sensor.

- Vertical and lateral pneumatic pusher-plates with pressure adjustable from the control panel.

- Product presentation: stepped, stacked, stepped-stack, individual slices, “shaved-meat”, oval shapes, one row beside another, different programmable figures, etc. The number of slices in each group may be varied according to requirements, as well as the length of the portions and the separation between portions.

- Cutting system - both circular and orbital rotation, with independent motors and independent speed control through the control panel to achieve a precise and parallel cutting.

- Easy adjustment of all settings using the touch sensitive screen of 15″ on the control panel.

- Equipped with automatic system of rear loading, with a high performance for products up to 1200 mm in length

- Automatic removal of residual pieces final product.

- Detection and auto correction of incomplete portions.

Options:

- paper interleaver - maximum 220 mm. Alternatively 2 rolls of 100 mm/each in parallel. Ref. ITE0600002C

- Dynamic weighing scale. Weighing table length 450 mm. Width weighing table 400 mm. Speed weighing 80-100 servings / minute. Maximum weight portion 1000gr. Ref. ITE0600003C.

- 500 mm flip/flop rejection conveyor for rejecting the portion on upper conveyor-belt. Ref. ITE0600009C.

- Side rejection conveyor. Width: 300 mm and length: 500 mm. Side rejection in the same lower conveyor-belt. Ref. ITE0600004C.

- 2000 mm long upper conveyor-belt for checking rejected portions. Ref. ITE0600006C.

- 2000 mm long lower conveyor-belt to move portions to the thermoforming machine. Ref. ITE0600005C.

- Portions design through collector belt insertion movements that allow presenting the product in round plates, different figures, etc. Ref. ITE0600007C.

- Lateral displacement of 150 mm. Software portions design. Ref. ITE0600007C.

- Fold device of slices. Ref. ITE0600010C.

- Connection to scanner “ECO-SCANNER”. Ref. ITE06500002C.