Clippers

|

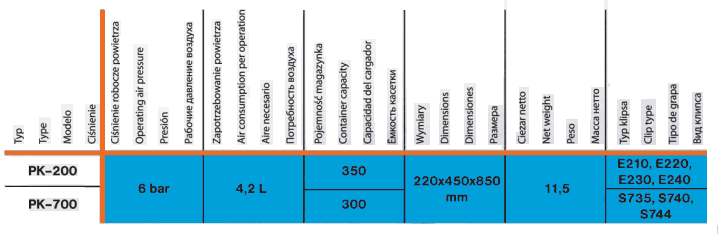

Single clipper BPK-200/700

A universal clipper to close, using an aluminium clip, plastic, natural casings, nettings and bags. It is used by small and big food processing plants (meat processing plants, dairies, agricultural producers, aquarium shops). Material used for production warrant that the machine can work for a long time and is easy to clean. Novel technical solutions including the innovative structure of the cylinder with built-in control elements have greatly improved safety, ergonomics and durability and make the machine very easy to clean and operate. Clippers are manufactured in two sizes: BPK-200 – for clips of the E210, E220, E230, E240 series BPK-700 – for clips of the S735, S740, S744 series Standard accessories:

|

Parameters:

Gallery

|

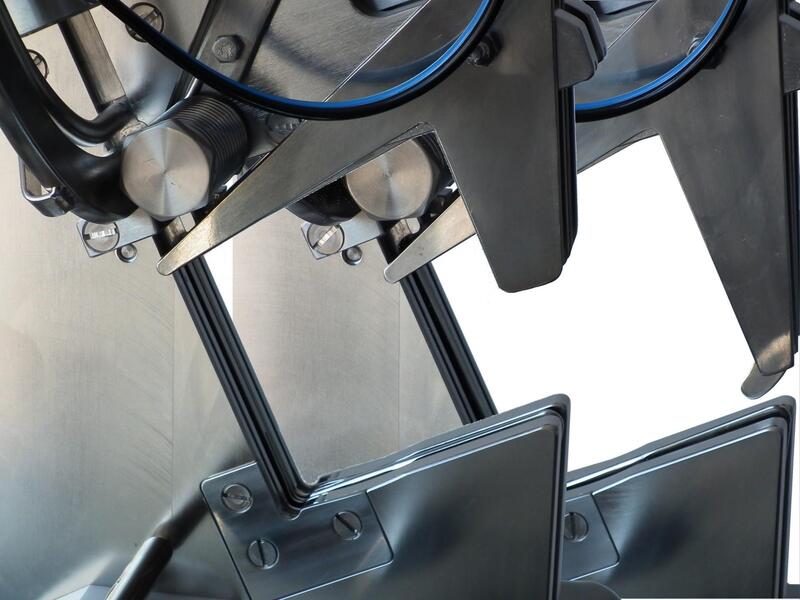

Double clipper BDC-200 MT Clipper BDC-200 MT is an easy-to-use, dependable device for closure of casings. It performs well in packaging sausages, cheese and other products and uses all casing types used in food processing industry. A new stainless steel cylinder type and its new design make the machine much easier to clean. Advantages:

Learn what the BDC 200 clipping machine can do:

|

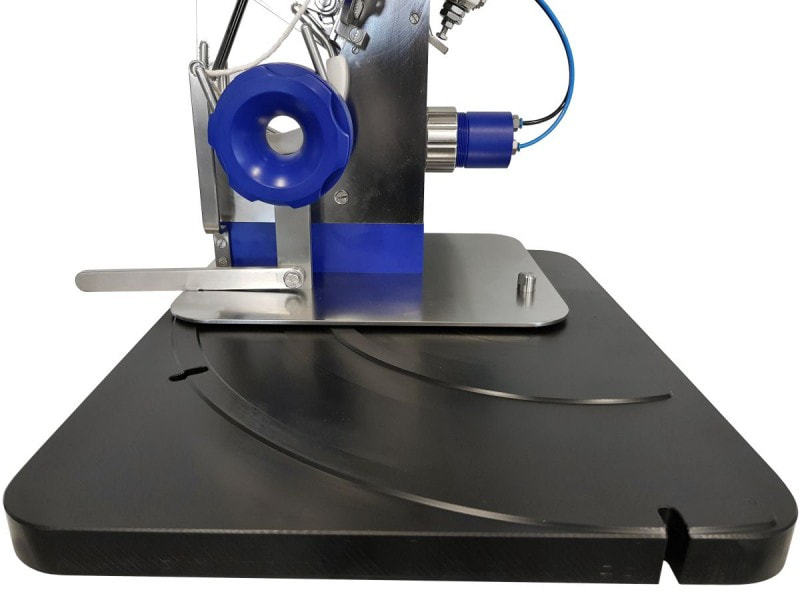

BDC200 MR two-row, rotary clipping machine

The BDC-200 MR rotary clipping machine is a new type device that is a development of the BDC-200 MT two-row table clipping machine. It is an easy-to-use, universal and reliable device for fast closing of various types of casings with a diameter of 25 to 100 mm. It is perfect for packaging a wide range of products such as sausages and processed cheeses. Thanks to the standard stuffing pipe, combined with the adjustable casing brake and the rotating base, the clipping machine can be connected with the stuffer.

An additional advantage is the redesigned pneumatics, which allowed to increase clipping speed up to 10% - 20% per cent in comparison to our previous versions.

Advantages:

Discover the possibilities of the BECK BDC-200 MR clipping machine.

An additional advantage is the redesigned pneumatics, which allowed to increase clipping speed up to 10% - 20% per cent in comparison to our previous versions.

Advantages:

- a wide range of diameters of the clipped casings (25-100 mm)

- clipping all casing types

- possible to open, swivel base in the range of 60 and 90 degrees allows easy access to the stuffing tube and placing further casings without necessity of clipping machine moving on the table

- a wide, low-mounted handle bar influences on proper and ergonomic operation

- handy cutting knife valve

- no need to use guide trays

- large clips magazines and easy to clean

- The above functional values, as well as constant and quick access to spare parts make working with our clipping machine easier, faster and very effective.

- last but not least is cost lot less than a semi automatic machines on the market

Discover the possibilities of the BECK BDC-200 MR clipping machine.

Semi-automatic clipper BDC-200 SM

|

The semi-automatic double clipper is used with all casing types from a diameter of 30 to100 mm, and for polyamide casings – up to 140 mm. Semi-automatic clippers are mechanically connected with a sausage stuffer with the portion control. Using the electric connection between the stuffer and the clipper– the stuffer starts after each clipping. Standard accessories:

|

|

Automatic clipper BDC-700 AM

|

The double automatic clipping machine is a universal and efficient machine for both small and large processing plants. As it uses S700 clips it is perfect for closure of all casing types. The machine is compatible with every stuffer equipped with the portion cutter and communication line. The clipper sends a signal to start feeding of the stuffing, and then the stuffer sends back the signal of the portion end and clipping is made.

Automatic clipper BDC-700 AM has two types of clip closure adjustment and thus the machine can be very precisely set even for delicate casings. Adjustment methods:

- hardness of the casing filling - pressure of the clip closure - number of portions per cycle - adding the loop - cutting the casing between clips |

Technical parameters:

Standard accessories:

Additional accessories:

- Diameters of casings to be clipped 30-140 mm (depending on the funnel used, brake and type of the casing and stuffing).

- Working air pressure of 6.0 bar

- Compressed air consumption of 15 l/cycle (depending on the clipping speed – minimum 550 l/min)

- Capacity of clip containers. 2 spools of 2700-3600 clips (depending on the clip size)

- Clip type S 735, 740, 744, of various hardness.

- Machine dimensions: 1200 x 720 x 1550 mm (width x depth x height)

- Net weight: 65 kg.

- Capacity 30-40 cycles per minute (depending on parameters set and correct preparation of the compressed air connection)

Standard accessories:

- Automatic cutting of the casing between clips

- Additional elements to adjust the knife to make it easy to have the ends clean

- Manual adjustment of the clip closure

- Programmable adjustment of the clip closure

- Automatic loop feeder

- Automatic clip feeder

- Adjustable tray on rollers for easy transport of the portion

- Casing end detector

- 1 set of the stuffer and the brake

- 1 set of special spanners

- Operation and maintenance manual

- Carriage with turning wheels

- Compressed air preparation station

Additional accessories:

- Automatic string dispenser

- Additional stuffing horns with a diameter of 20-45 mm

BDC-700 AM-S Automatic clipper

The double automatic clipper S-version is another variant of the BDC-700 AM clipper. Thanks to the operation with S-700 clips, it is perfect for closing all types of casings. The machine is compatible with every stuffer equipped with the serving cutter and communication connector. The automatic clipper has two types of clip closure adjustment. This allows smooth and precise setting of the machine even when clipping delicate casings.

The S-version operates with clips in the sticks. That makes equipping the machine with an automatic clip feeder unnecessary. Such a solution allows you to offer a more favorable price while maintaining the advantages of the automatic clipper.

The S-version operates with clips in the sticks. That makes equipping the machine with an automatic clip feeder unnecessary. Such a solution allows you to offer a more favorable price while maintaining the advantages of the automatic clipper.