BS 47 - MAP Packaging , Skin packaging, Tray sealing

The automatic tray sealing machine has a vacuum and protective gas function for producing MAP packaging. It wins people over thanks

to its high level of user-friendliness and a service-focused design in line with demanding hygiene regulations.

to its high level of user-friendliness and a service-focused design in line with demanding hygiene regulations.

|

Technical data

|

|

Construction

BS packaging machines are only made from high-quality individual components such as stainless steel and Peraluman aluminum alloys. They guarantee long-term operational capability and meet the requirements of protection rating IP 55 with their splash-proof elements, clear structure, robust engineering and well-thought-out design. |

|

User-friendliness

The Siemens programmable logic control (PLC) is equipped with a precision sensor and a clear “Touch Screen” control panel which makes precise setting of important operating parameters possible. These can be tailored individually to suit the foil and tray properties and different tray depths. |

|

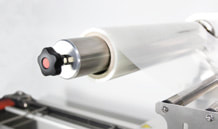

Sealing

The perfect interaction of stable sealing temperature and constant contact pressure guarantees optimal packaging outcomes. The tray check on the input side triggers the sealing automatically; the printed foil is identified by a photocell and positioned correctly. The punched foil is collected by a surplus foil winder. |

|

Productivity

The automatic tray feed makes a high capacity possible with low personnel engagement times. A change of format can easily be effected with exchangeable tools and this guarantees quick readiness for operation. The wide range of standard tools guarantees quick response times. Customer specific sealing frames can be produced if required. |

|

• Integration into existing packaging lines

• Conveying speed variably adjustable • Photocell for identifying print marks • Variable for different tray sizes |

•Service friendly design • Optimal accessibility • Stainless steel housing • Sealing frame easy to change |

• Vacuum and gas controlled by digital

vacuum gauge - PLC control • Safety valve for use of gases with an oxygen concentration > 21% |

|

| ||||||||||||

|

BS 52 Tray Sealer

Maximum sealing: 400 × 275 mm Maximum shell height: on request Cycles: 8 - 10 / Min. External dimensions: 2,50 × 0,99 × 1,66 m * Maximum film width: 470 mm Compressed air supply: 6 bars Weight: 410 kg Electrical connection: 3 phases, 220V, 60 Hz** Power: 1,7 kW * w × d × h ** Special voltages on request |